How Design Automation Reduces Design Time for Metal Furniture Manufacturers

Metal furniture manufacturers in today’s times are often unable to scale product deliveries on time due to customized designs. With CAD platforms alone they need manually customize drawings for every custom order. In fact, along with drawings, BOMs, DXF files, and all neutral file formats need revisions. It results in lengthy design cycles and increased engineering lead times.

For example, to implement any design change request, the manufacturers have to get the involved designer before implementing it. The traditional design process elongates the total design cycle time especially while dealing with design iteration. The customer is left frustrated with endless wait time and goes away.

Design automation, on the other hand, automates these iterative processes using logical rules to accelerate design cycle. It enables same-day manufacturing as the order confirmation and customers have shorter wait periods.

Prime factors affecting custom metal furniture manufacturing

- Customization demands: A customer always asks for personalized features in every piece they buy. All these requests go through a lengthy approval process for engineering validations and delay manufacturing.

- Tooling capabilities: Custom designs demand discrete tools like drill bits, fasteners, cutters, etc. for every order. It consumes an incessant amount of time in changing the machine set up and raises several change orders that need to be fixed. The manufacturing comes to a standstill until a new setup or resolution of change orders.

- Repetitive design tasks: Manual tasks like generating custom drawings and models are prone to errors and take hours of the designer’s time.

- There is an obvious need among metal furniture manufacturers to reduce design time with the use of design automation tools and efficient 3D product configurators. Implementing design automation helps manufacturers scale custom design processes, reduce manufacturing time, and help sales teams stay informed.

How design automation can reduce design time for furniture manufacturers

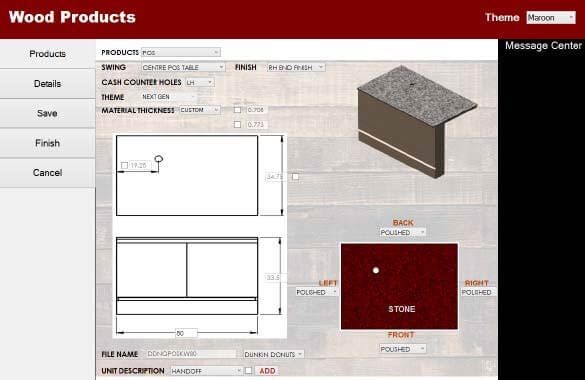

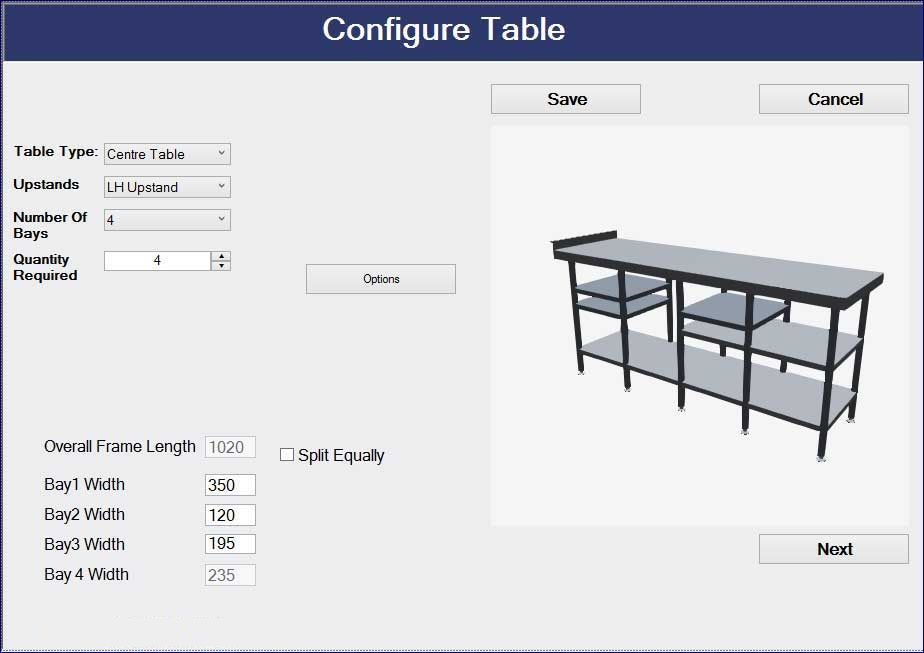

Design automation with DriveWorks deployment enables design customization with manual changes in design parameters for manufacturing drawings and models.

Implementing DriveWorks can automate the design and modeling process, quicken approvals, and lower the time to market speed considerably.

1. Accelerated design development

Custom product manufacturers who deliver the goods based on customer requirements have to rely on multiple design iterations. They spend an immense amount of time on design approvals and testing their products which also leads to higher expenses.

DriveWorks helps in automating repetitive design tasks ensuring:

- Rapid elimination of errors and inadvertent design changes.

- Empowered sales team relying on 3D design visualization.

- Automation of all custom model generation as per standards.

These factors collectively reduce the overall design lead time. For one of our clients, our design automation engineers reduced lead time for a US-based metal furniture manufacturer. They accelerated the design cycle by an unbelievable 70 times after implementing with a DriveWorks certified partner. These automation specialists can set definite rules to eliminate repetitive tasks for metal furniture product manufacturing.

2. Automated manufacturing documentation

Manufacturers find the manual generation of manufacturing process data tedious while being prone to errors.

The 3D product configurator attribute from DriveWorks offers designers the ability to create manufacturing designs automatically and accurately. The feature automates manufacturing data and other documents from approved CAD models. Creating BOMs would hardly be a hassle, anymore, with the absence of glaring errors on annotation text, manufacturing notes, positions, etc.

They can also centralize and maintain error-free and updated design data to use it for documentation. It enhances the overall productivity of the engineer and enables initiating manufacturing on the same day.

3. 100% accuracy with automated sales quotes

Metal furniture manufacturers who deliver customized products can win customers with precision, personalization, and quality. However, to manage higher volumes of new business, one should be able to simplify the buying process.

Enter the automated sales configurator, an integral feature of DriveWorks. It integrates with legacy business systems like ERP and CRM to get up-to-date data, material costs, customer details, etc., and create custom and accurate sales quotes. Since these quotes are created based on approved models in DriveWorks, they meet 100% accuracy and need no separate quality checks.

The integration of DriveWorks with SolidWorks and enterprise systems offers:

- Generation of prompt sales proposals helps the sales guys to focus on winning more leads and driving sales revenues.

- Showcase the entire product range and get instant quotes, and the delivery date accurately during placement of orders.

- Reduced costs due to errors or incomplete product proposals.

- No need to build another sales configurator for the existing system.

DriveWorks guides customers during the sales process better than any other. Get prompt insights for cross-sell and up-sell opportunities to existing clients.

We recently delivered the solution with 100% accuracy in custom quotes for a UK-based table manufacturer. The engineering firm set up a custom sales configurator to help them respond to client queries on time.

Conclusion

Implementing DriveWorks helps metal furniture manufacturers to reduce design lead time by automating their regular design customization tasks. The platform automates the entire sales-to-manufacturing process while generating 3D models, manufacturing documents, and sales quotations within clicks.

The ability to generate custom designs easily and at reduced costs is paramount for many furniture manufacturers. No wonder, many furniture design engineers now have implemented DriveWorks to reduce the time for all design cycles. What’s more, the software eliminates mistakes with highly accurate designs to deliver stylized products to clients quickly. It simplifies the changes involved in views or alterations without any fuss.

The integration ensures that users can customize furniture pieces according to their space and requirements. All they have to do is create product family designs in SolidWorks, and implement DriveWorks to automate design customization, effectively.

Authored by:

Usha B. Trivedi is an engineer and she contributes in-depth articles for mechanical and industrial equipment designs, furniture designs, and the fabrication sector. Her contributions are primarily focused on enabling engineering professionals, furniture manufacturers, and fabricators to optimize design outcomes through CAD and CAE tools.